|

Global Supplier Chain

Management System for OEM/ODM Business

Global Supplier Chain

Management System for OEM/ODM Business

Overview

A German importer of hardware and building

materials.

This company has an engineering development

and testing center in Germany, an office in Singapore, and

a team of inspectors located in Shanghai, China. Most of

their 100 suppliers are located in China.

Major

Issues

Prior to employing QIT Supply Chain

Management System, the company did not utilize a computerized

system for the handling of their inspection standards and

inspection records.

The engineering center in Germany complained

that the inspection team was using the wrong inspection

standards and lost tons of money on defective parts

The engineering team in Shanghai complained

that the Engineer Team did not provide an up-to-date inspection

standard and in some cases, some products don't even have

product Specís and inspection standards. The mismanagement

of engineering standards had caused a lot of confusion and

mistakes from their team.

By employing QIT's system, F company was

able to implement a new business process that effectively

linked the engineering team, inspection team and the suppliers.

Solutions

and The New Business Process

-

The engineers in Germany now enter

the product Specís and inspection standards into one

centralized database. For the obsolete Specís, the engineers

in Germany are now able to remove them from the system

-

The inspection team in China now can

pull up the same product Specís each time they plan

a lot inspection

-

The inspection team is able to enter

the inspection results into the system from various

locations in China

-

The suppliers can also enter their

inspection results to the same system

-

The QA manager is able to review the

lot dispositions and issue deviation requests to customers

in Germany

-

The customer service team in Germany

now can print out the the inspection reports and supplier

inspection reports

-

All the suppliersí performance data

can be seamlessly shared with the users in Germany,

Singapore, China, or any place around the world

-

The QA managers can access the data

and make decisions even when he is away from his main

office. Due to the prompt decision making abilities

that the system has prompted, the company is now saving

millions dollars

The

specific results have been very impressive

-

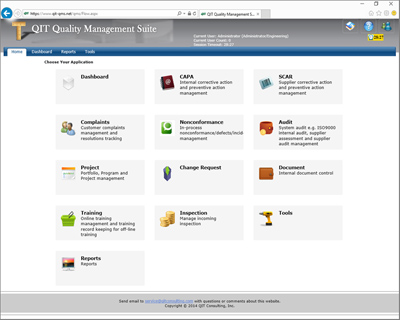

Deployed a next-generation CAPA system

incorporating Company A's specific modifications at

an affordable cost

-

Implemented a world-wide project bringing

together their engineering teams, inspection teams,

suppliers and customers from around the world

-

No headcount increase was needed to

facilitate and maintain the program

-

Cultivated a collaborative quality

culture

-

Purchasing, Quality and Supplier Management

Departments from around the world now share real-time

information online

|