|

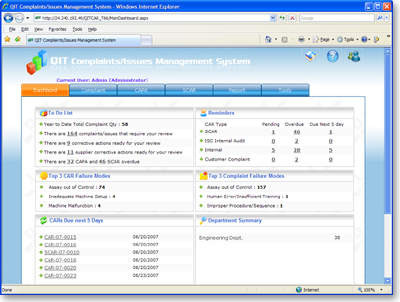

Customer Complaints/Nonconformance Management System

Customer Complaints/Nonconformance Management System

Overview Overview

A major US household product manufacturer,

which has

-

A Call Center

in the US

-

10 distribution

centers around the world

-

8 manufacturing facilities in China

-

Over 150 OEM suppliers around the

world

Major

Issues

Prior to employing QIT Customer Complaint

Management system, the company used a database based on

Lotus Note to management customer complaints.

-

The QA engineers spent 60% of their

time on tracking CARs with local factories and OEM suppliers

and prepared reports for senior management.

-

Ironically, similar problems happened

again and again despite the local factories and supplier

have reported the root causes have been resolved.

Solutions

and New Business Process:

-

Step 1- Implement the Program and

Collect Data:

-

Customers/consumers in the US

and UK are able to submit their concerns and complaints

through internet

-

Customer service representatives

at the call center in the US are able to log in

customer complaints from 800 service calls, emails

and faxes

-

Sales representatives around the

world are able to enter customer complaints and

any concerns about the products

-

Step 2 - Analysis the Data, Define

Key Issues and Issue CAR

-

QA Managers in the US HQ and China

divisions are able to review and analysis customers

complaints and define failure mode and customer

usage pattern

-

QA managers and engineers then

are able to issue CARs right after the product audits

or whenever any issue was found

-

Step 3 - Resolve the Key Issues

Specific results:

-

Establish a global problem solving

system in just few months with a affordable cost

-

No headcount increase was needed to

facilitate and maintain the program

-

Customer Service, Sales, Quality and

Supplier Management Departments from around the world

to share real-time information online and focus on providing

effective solutions for customers issues

-

Cost saving of 2 million/year* by

effectively communicate the issues

-

Shortened problem solving cycle-time

by 50%

Specific results:

|